A Pre-Engineered Metal Building (PEMB) is a type of construction method where the components of a building are designed, fabricated, and assembled using a standardized set of engineering principles and manufacturing processes. These buildings are typically composed of steel structural members, which are pre-fabricated off-site and then transported to the construction site for assembly.

Key characteristics of pre-engineered metal buildings include:

1. **Standardization:** Pre-engineered metal buildings are designed using standardized components and systems. This allows for efficient manufacturing and assembly processes, reducing construction time and costs.

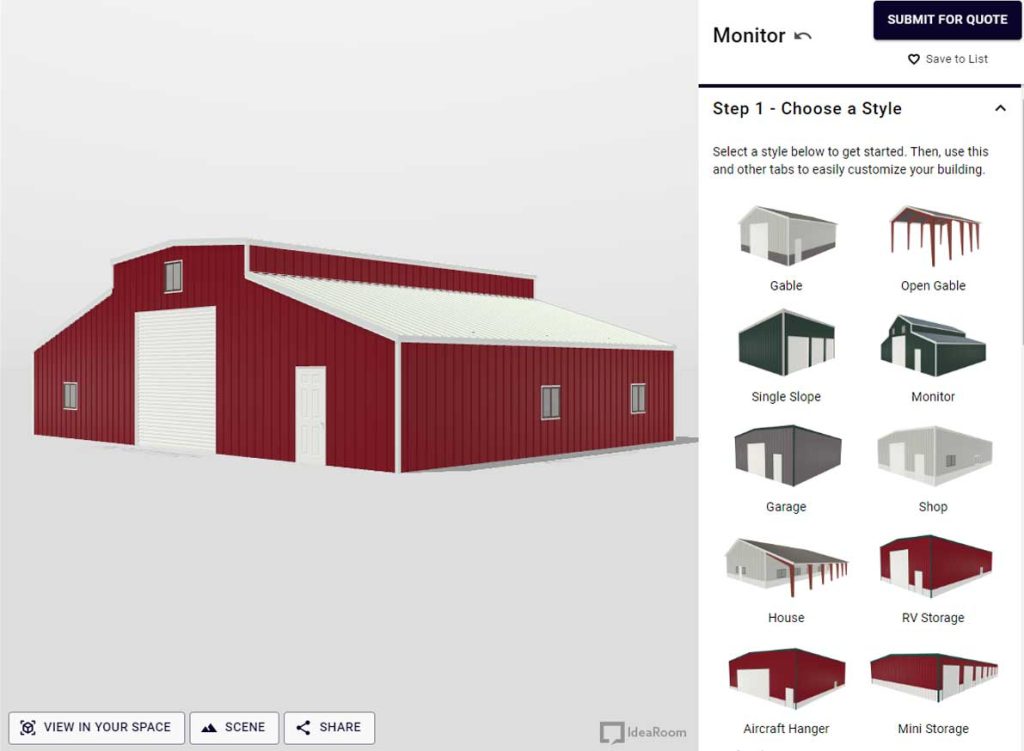

2. **Customization:** While the components are standardized, pre-engineered metal buildings can be customized to meet specific size, layout, and functional requirements. This customization is achieved by adjusting the dimensions, roof slopes, wall configurations, and other elements.

3. **Efficiency:** The components of a PEMB are manufactured in a controlled factory environment, which often results in higher precision and quality compared to on-site construction. This efficiency can lead to faster construction timelines.

4. **Cost-effectiveness:** Due to the standardized design and manufacturing processes, pre-engineered metal buildings can be more cost-effective than traditional construction methods. The reduced construction time and labor costs contribute to overall savings.

5. **Durability:** Steel is a durable and strong material, making pre-engineered metal buildings resilient to various environmental conditions, including wind, snow, earthquakes, and more.

6. **Versatility:** Pre-engineered metal buildings are used for a wide range of applications, including warehouses, industrial facilities, agricultural buildings, commercial structures, storage facilities, sports complexes, and more.

7. **Sustainability:** Steel is a recyclable material, and the fabrication of components in a controlled environment can help minimize waste. Additionally, the long lifespan and low maintenance requirements of steel buildings contribute to their sustainability.

Overall, pre-engineered metal buildings offer a streamlined and efficient construction solution for various types of structures. They are favored for their cost-effectiveness, speed of construction, and adaptability to different project requirements. Keep in mind that the construction industry is always evolving, so there might have been developments or changes in this field since my last update in September 2021.

A Pre-Engineered Metal Building (PEMB) is a type of building structure that is designed, fabricated, and assembled using a combination of standardized building components. These components are manufactured off-site and then shipped to the construction site for assembly. PEMBs are known for their efficiency, cost-effectiveness, and versatility, and they are commonly used in a wide range of applications, including industrial, commercial, agricultural, and even some residential buildings.

Key characteristics and components of a Pre-Engineered Metal Building include:

1. Structural Framework: PEMBs typically have a rigid structural framework made of steel columns, beams, and other components. These components are engineered and fabricated to precise specifications.

2. Roofing and Wall Systems: The roofing and wall panels used in PEMBs are often made of metal, such as steel or aluminum. These panels are designed for durability and can provide insulation and weather protection.

3. Secondary Framing: In addition to primary structural components, PEMBs include secondary framing elements like purlins and girts. These components provide additional support for the roofing and wall panels.

4. Customization: Pre-engineered metal buildings can be highly customizable in terms of size, layout, and appearance. They can be adapted to various architectural styles and can accommodate different functional needs.

5. Speed of Construction: One of the advantages of PEMBs is their fast construction time. Since many of the components are pre-manufactured, on-site assembly is typically quicker than traditional construction methods.

6. Cost-Effective: PEMBs are often considered cost-effective due to their efficiency and reduced construction time. They can also be cost-effective in terms of long-term maintenance and durability.

7. Versatility: These buildings are used for a wide range of purposes, including warehouses, factories, retail stores, aircraft hangars, sports facilities, agricultural buildings, and more.

8. Sustainability: Some PEMBs are designed with sustainability in mind, incorporating energy-efficient features, insulation, and even solar panels.

PEMBs are a popular choice for many businesses and industries due to their flexibility, speed of construction, and cost-effectiveness. They are particularly well-suited for applications where a large, open interior space is required, making them a common choice for warehouses and industrial facilities. However, they can be adapted for various other uses as well.